Select your region / language

Industrial software - Maestro+

Maestro+ is the perfect warehouse software solution to boost the overall performance of your automated production. It is web-based, efficient, cost effective, user friendly, multilingual and fully modular.

Benefits

- Real-time overview

- Reduction of the operators handling time

- Minimised paperwork

- Full fledged

Modules

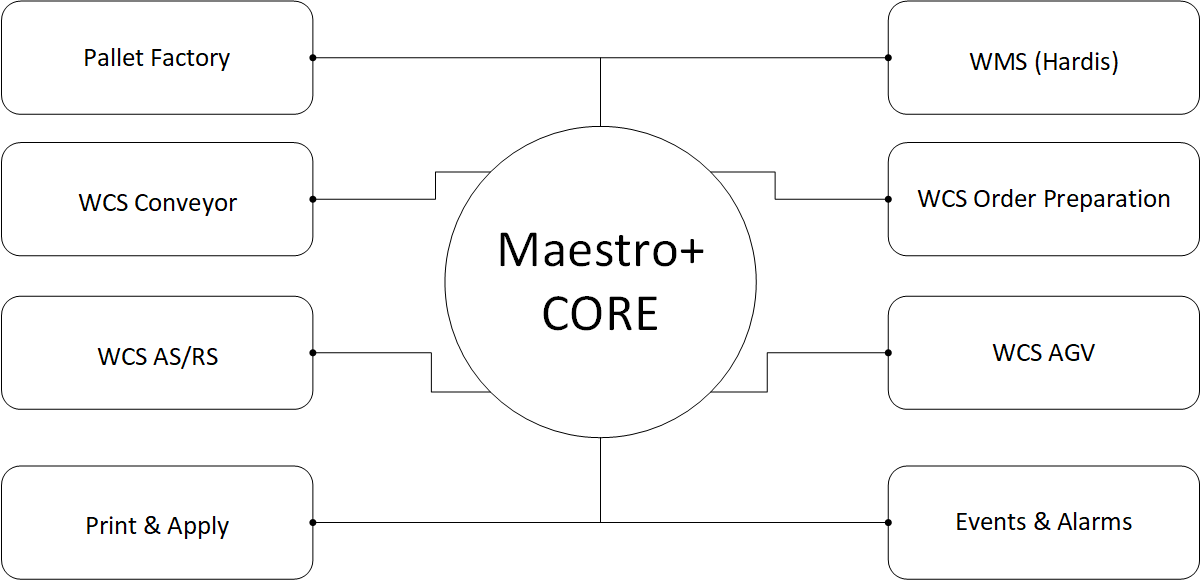

Maestro+ Core

The CORE module is the heart of the system, and forms the foundation for all Maestro+ modules.

It provides the modules with the necessary data structures:

locations - articles - resources ...

Maestro+ can communicate with third party hardware.

Modules are web based applications, and available on devices such as handheld android scanners, mobile devices, tablets, etc.

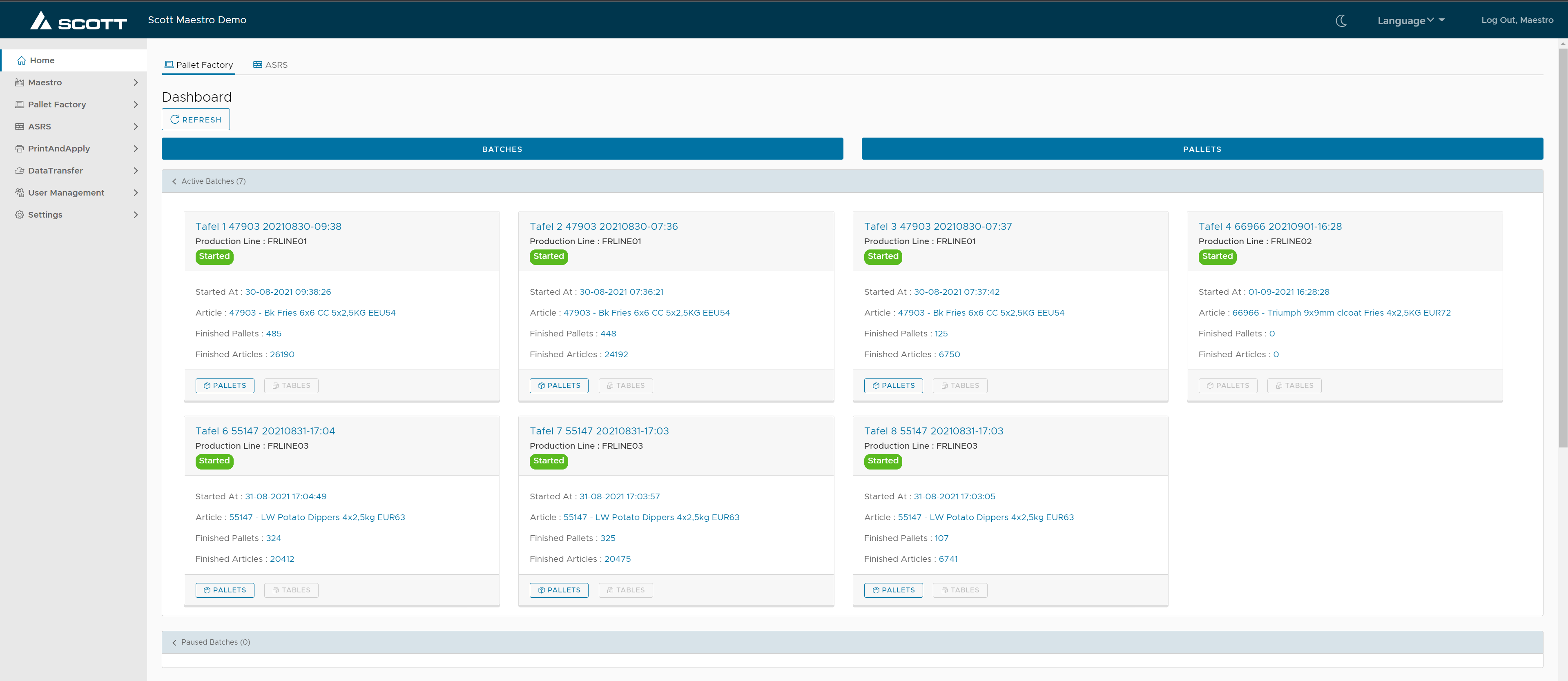

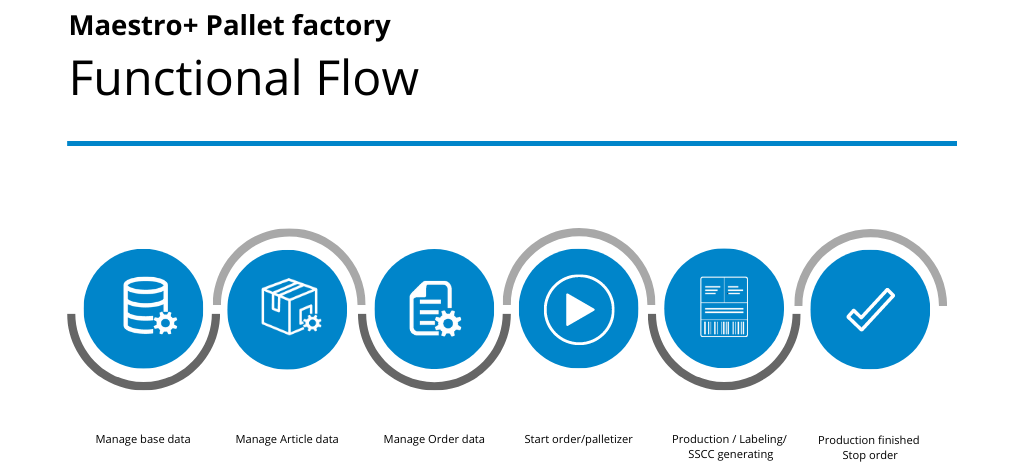

WCS Pallet Factory

Controlling all automated palletising systems. Bringing them closer to production and maximizing the utilisation of the installation.

The Maestro+ WCS Pallet Factory manages:

- The master data required for palletising

- Order management

- The palletising flow for single and multiple production lines

- A connection with the production line with integrated traceability

- Default integration with Scott palletisers

WCS Conveyor

Product flow handling in the warehouse is managed by the WCS conveyor module. Communicating through default interfaces real time with the PLC.

- Allocation of handling units with data

- Controlling products flow

- Triggering events to other modules via attribution (e.g. to print labels)

WCS ASRS (Automatic Storage & Retrieval System)

To manage and control the automated warehouse the WCS ASRS module is implemented.

- Interfacing with miniloads (boxes) or stacker cranes (pallets)

- Mission management & optimization

- Load management & optimization

WCS Order Preparation

There are many ways to organize the order picking process.

This module can be used for various ways of automated order picking:

- Handheld scanners

- Pick-to-light

- Pick-to-…

WCS AGV (Automated Guided Vehicle)

The following items are managed in the WCS AGV module:

- Distance optimization

- Mission management

- Charging management

- AGV management (status, history, …)

- Battery efficiency

Print & Apply

Managing & labelling with all ZPL labelers.

The module monitors all labelers and anticipates operator interventions. In case of maintenance the labels can be sent to backup labeler for manual application.

Alarms & Events

This module presents operators a real-time events status of the installation, which captures, monitors & visualizes everything.

- Integration from third-party systems

- Filter & search bottlenecks

- Export data, allowing integration in any 3rd party too

- Reporting on frequent alarms

Alarms: When a certain warning or alarm occurs on the installation, this module provides users more detailed information.

Events: an event is generated for every action done in the software such as: printing labels, interfacing with 3rd party software, decision made on position x and many others.

Cockpit

The cockpit was designed to give a detailed insight of the performance.

What the load factor of the palletisers are, potential bottlenecks in the installation, energy usage, etc. If there is, for example, a drop in output, the cockpit will be able to trace this back to the origin. The cockpit allows the customer to have capacity and occupancy monitoring and planning trough KPI’s.

Related Solutions

Automated Pick and Pack order picking system