Select your region / language

Meat processing

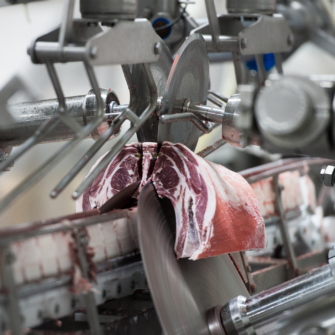

Scott meat processing systems are designed and manufactured to improve product yield, throughput and efficiency, while increasing operator and food safety. We offer a wide range of automated and semi-automated solutions.

Scott meat processing systems are designed and manufactured to improve product yield, throughput and efficiency, while increasing operator and food safety. We offer a wide range of automated and semi-automated solutions.

Global leaders in meat processing solutions

Our automated meat processing solutions offer a multitude of benefits, including productivity, throughput, efficiency and operator safety improvements for processors. Our equipment can replace or enhance traditional manual tasks, providing precise cutting to the exact specifications of each carcass. Composition grading, deboning, scribing and cutting are all available to beef, lamb, pork and poultry processors to improve their production lines.

Designed specifically for the meat industry, automated cutting equipment, supported by x-ray and vision technology, provides precise cuts and reduces health and safety risks. Smart technology maximises the value of carcasses through data and accurate cutting. Our X-Ray Primal System creates a 3D map of the bones within a carcass, providing the correct height and angle measurements for each cut. This data guides the cutting blades with an accuracy far greater than human capabilities, improving the quality and yield of each cut. Automation enables processors to extract more value from every carcass, resulting in a higher quality product, a fast return on investment and ultimately, improved competitiveness.

The increased yield comes from improved accuracy, which will have a positive financial impact...for instance, achieving an extra 5mm on French racks, compared to it being on the flap, is substantial.

Darryl Tones

ANZCO General Manager Operations